Ford Motor Co. will ask the United Auto Workers union for flexibility to reduce electric-vehicle production in case the US market for battery-powered cars lags behind expectations.

Negotiations open Friday for a new four-year contract for Ford’s more than 57,000 US hourly workers. And talks are expected to be contentious as the union seeks pay raises, a restoration of cost-of-living increases and job guarantees while the industry shifts to less labor intensive electric-vehicle production.

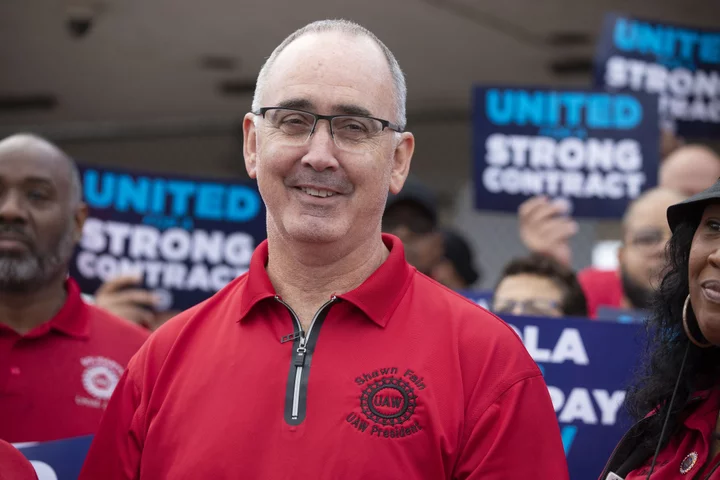

New UAW President Shawn Fain has said he is going to “war” against the Detroit automakers and accused them of engaging in a “race to the bottom” in the EV transition with factories that will employ fewer workers earning lower wages. This week, Fain eschewed the ceremonial handshake-across-the-bargaining-table with CEOs that has marked the opening of auto contract talks for decades, saying he’ll do so “when they come to the table with a deal.”

Ford will seek leeway in its $50 billion plan to boost EV production 15-fold to 2 million models a year by the end of 2026.

The company wants the ability to move workers to factories building the most in-demand models, whether they’re powered by electricity or traditional internal combustion, according to Ford officials who requested anonymity discussing internal matters. The current union contract restricts Ford’s ability to flex production, they said.

Read More: Biggest Auto Union Gears Up for Fight Over Battery Worker Pay

Ford has reason for caution. The US has been the slowest major market to adopt EVs, lagging behind China and Europe. Electric-vehicle sales growth in the world’s biggest economy slowed to just under 50% in the first half of the year, down from 71% during the same period in 2022, as inventories of battery-powered models ballooned.

Ford’s US EV sales fell 2.8% during the second quarter as it overhauled a Mexican factory to boost output of the Mustang Mach-E, while sales of the F-150 Lightning plug-in pickup grew just 4%.

Ford is hoping to convince the union to give it more flexibility by noting that it employs as many as 14,000 more US hourly workers than either General Motors Co. or Stellantis NV, parent company of Chrysler and Jeep. Having the biggest US hourly workforce costs Ford an extra $1 billion a year compared to its domestic competitors, the officials said.

Ford’s labor costs, including wages and benefits, are $64 an hour, compared to $55 an hour at the non-union assembly plants of international automakers such as Toyota Motor Corp. That creates a labor cost gap of $900 million with the international automakers, the people said. Labor costs at Tesla Inc. are even lower at $45-to-$50-an-hour.

Read More: EV Battery Workers Push for Union in Fight for Industry’s Future

Ford also plans to pledge to bring more EV manufacturing in-house to help offset the lower labor requirements, the people said. Chief Executive Officer Jim Farley has said controlling more elements of EV and battery production will give Ford a competitive advantage.

Last month, Farley penned a Detroit Free Press opinion piece defending Ford’s hourly compensation, which he wrote comes to $112,000 in annual pay and benefits. That elicited a sharp response from UAW Vice President Chuck Browning, who accused Farley of misleading the public and “utilizing old, musty and ineffective tactics.”

Farley is under pressure to reverse $3 billion in projected EV losses this year and achieve an ambitious goal of generating an 8% return, before interest and taxes, on battery-powered models by the end of 2026. Wall Street is skeptical that can be accomplished while boosting EV production to a level one analyst called “crazy high.”

Keeping costs in check is key to Farley’s ambitions. Since last summer when Farley said, “we absolutely have too many people,” Ford has cut thousands of salaried workers in the US and Europe.

New Factories

Meanwhile, the automaker also is adding thousands of production jobs at new battery factories in Tennessee, Kentucky and Michigan. But it is not yet clear if those new workers will be represented by a union or how much they will earn.

Ford’s highest paid production worker now makes $32 an hour, which the company says exceeds the pay of 90% of factory workers in America.

The UAW blasted Ford for taking a $9.2 billion US government loan to help finance three battery factories it’s building with South Korea’s SK On in Kentucky and Tennessee, calling it a “massive” handout to a venture creating “low-road jobs.”

The contract covering Ford’s hourly workers expires in mid-September.